FOR TWO DECADES, RF SAFE HAS SUPPORTED PATENT-FREE, OPEN-SOURCE PRODUCT DESIGN!

Audio PlayerOpen Source RF Safe Case Design! RF Safe has set the accessory phone safety standard since 1998. Rather than patent the best radiation safety design principles, we‘ve designed every product to welcome competition that follows the strictest standards. It is essential for our future that every phone case manufacturer and wireless device manufacturer understands how to enhance a user’s quality of life, not just provide a useful product experience.

Learn How It Works!

Why QuantaCase? Let’s Answer That!

Step-By-Step How To Make The Best Anti-Radiation Phone Case In The World! RF SAFE

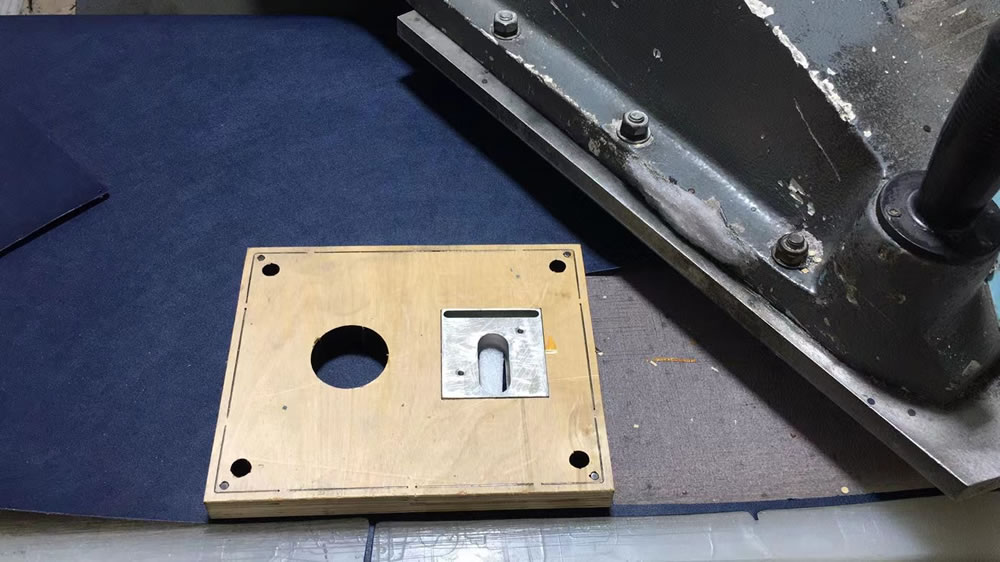

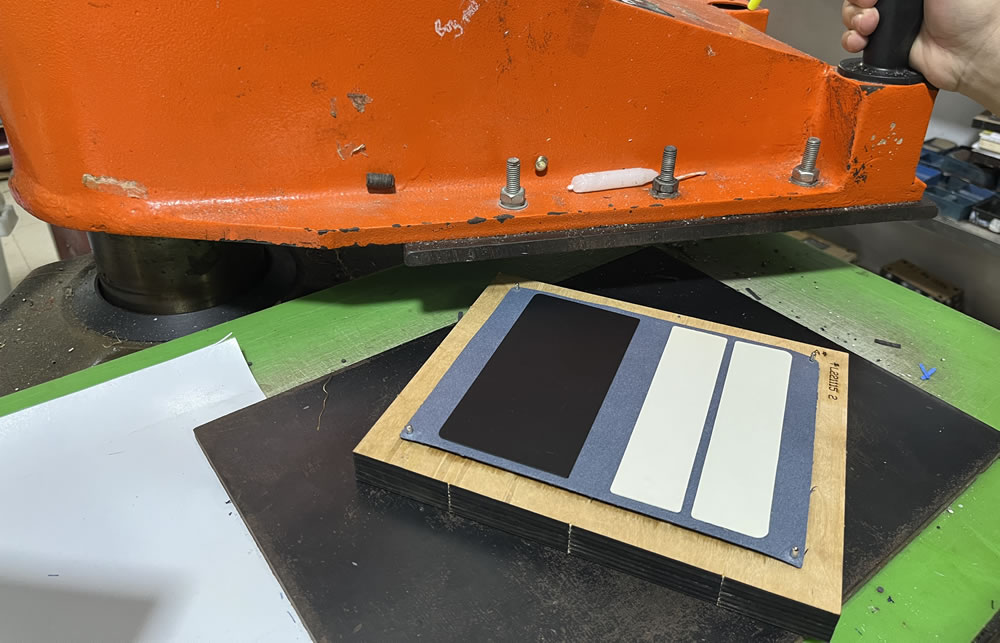

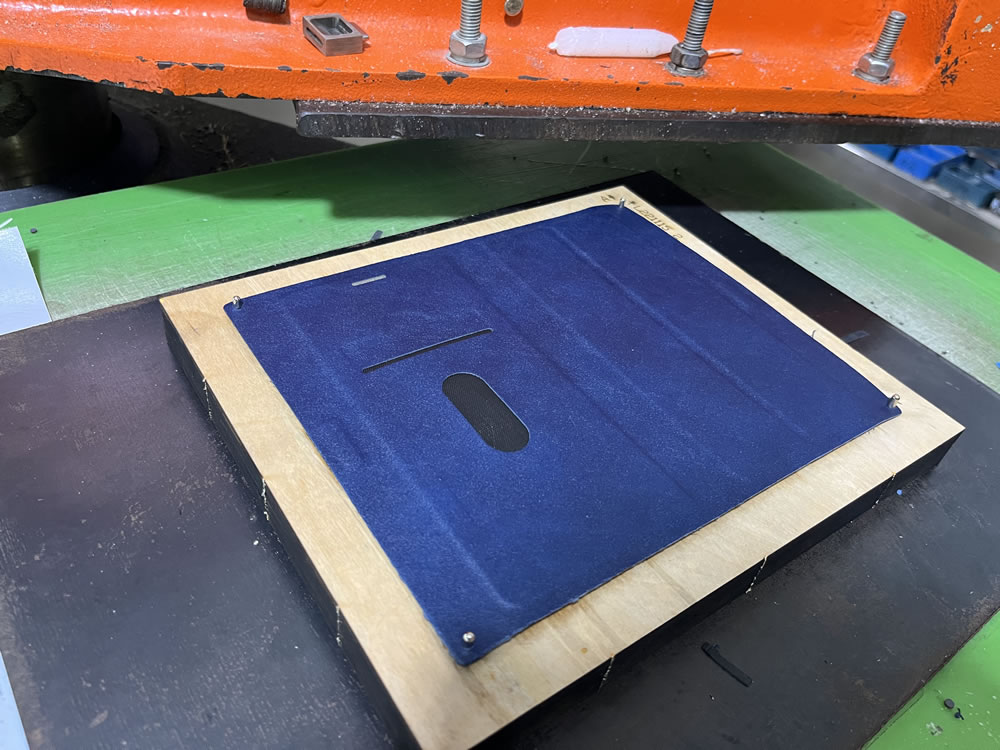

Using a press, the raw material used for the outer skin of the case is cut to begin the case manufacturing process, where components will be added by hand between these non-conductive material layers. Industrial presses are used in five different steps to manufacture a QuantaCase

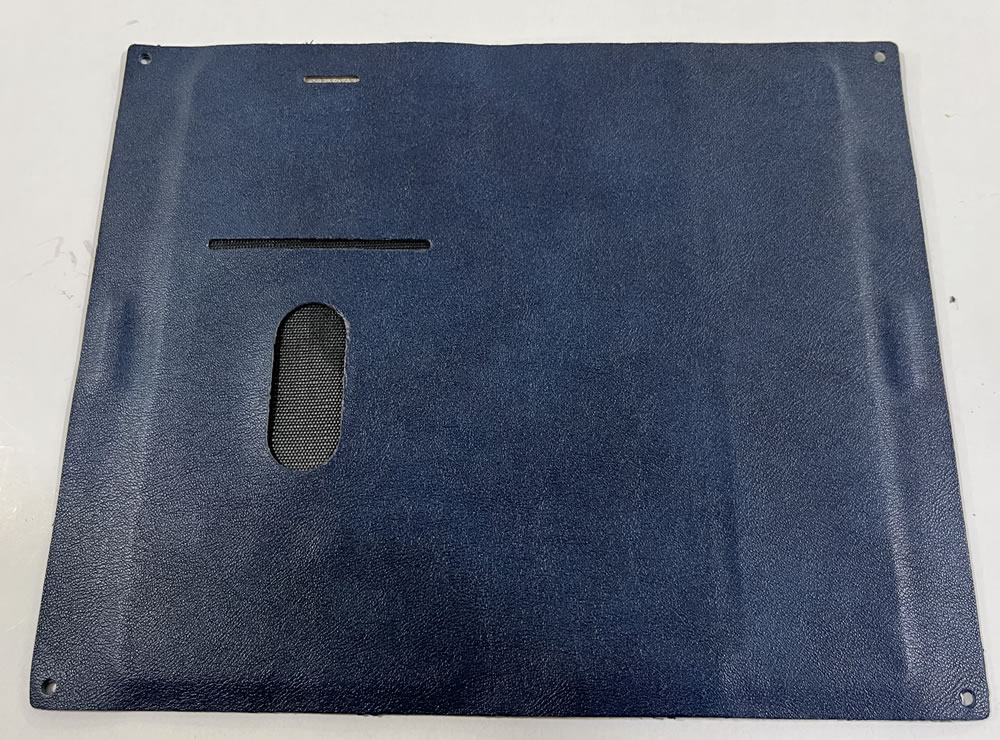

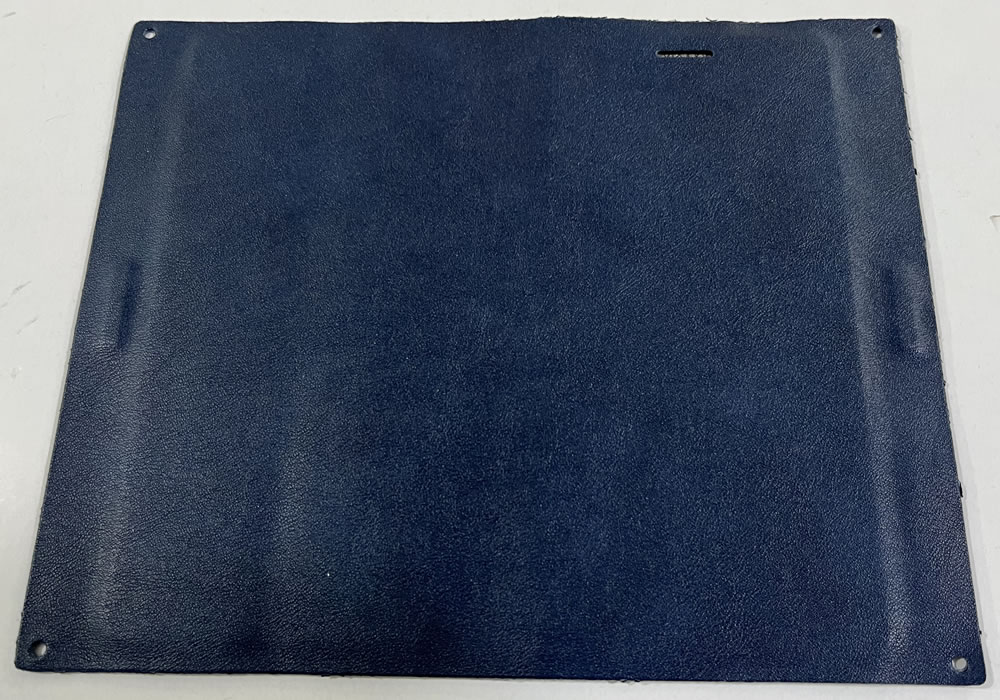

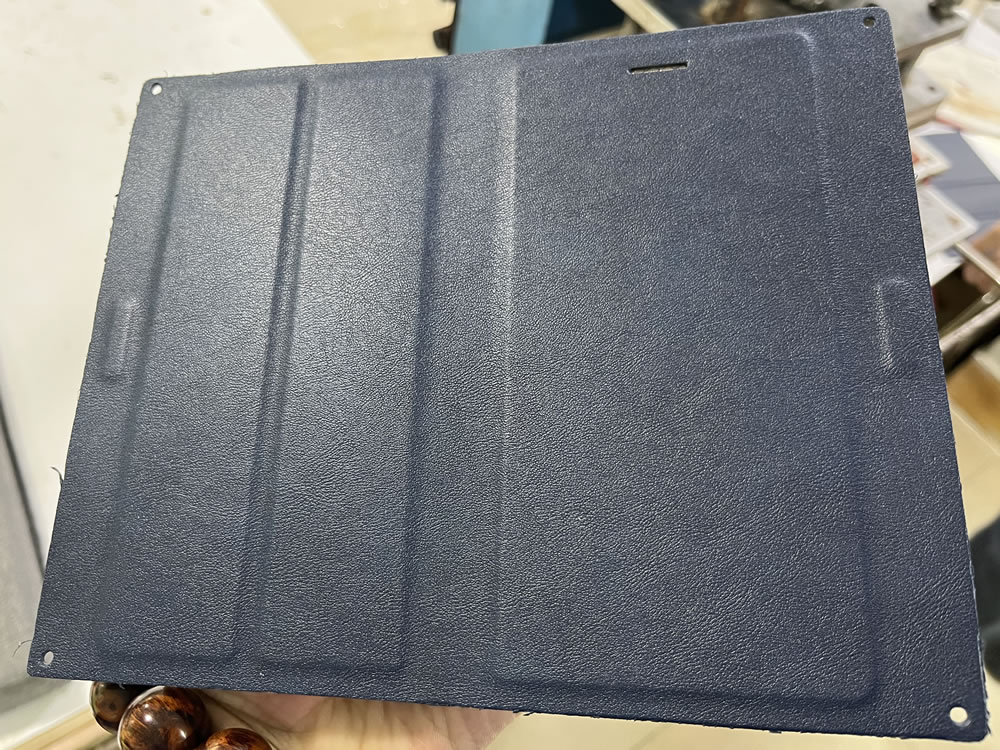

The finished cut pieces are precise every time. To ensure precision alignment, holes are cut at each corner to center the inner and outer material layers of the QuantaCase

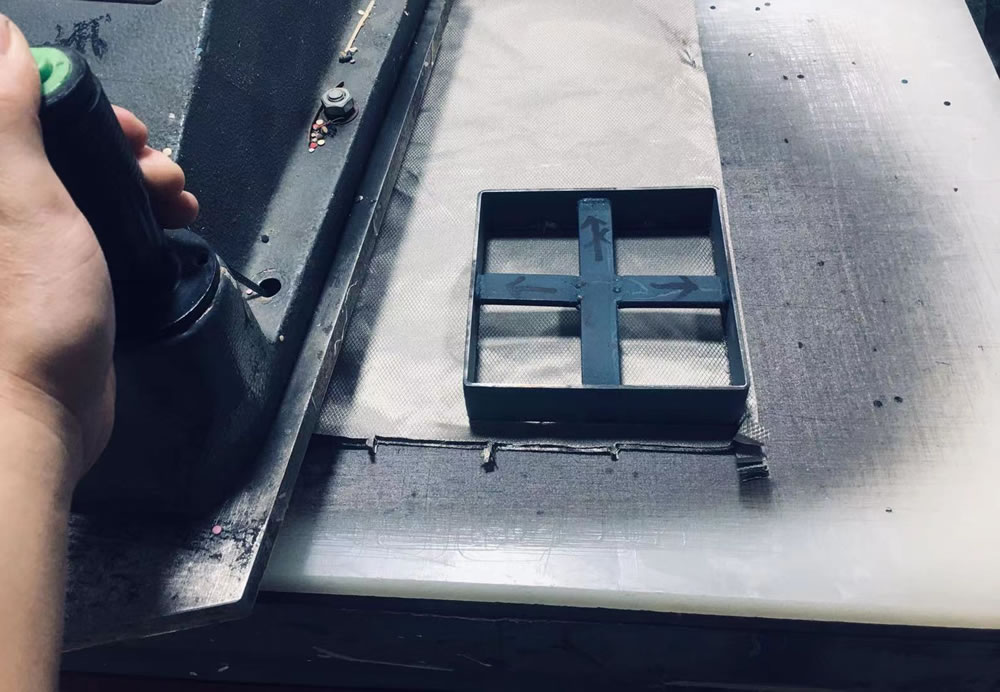

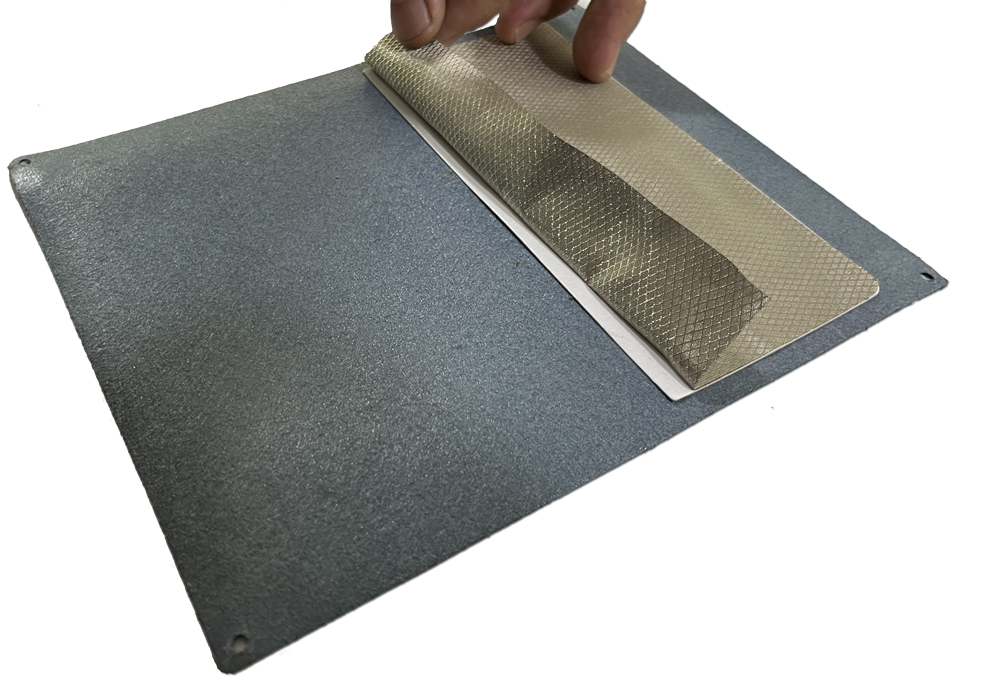

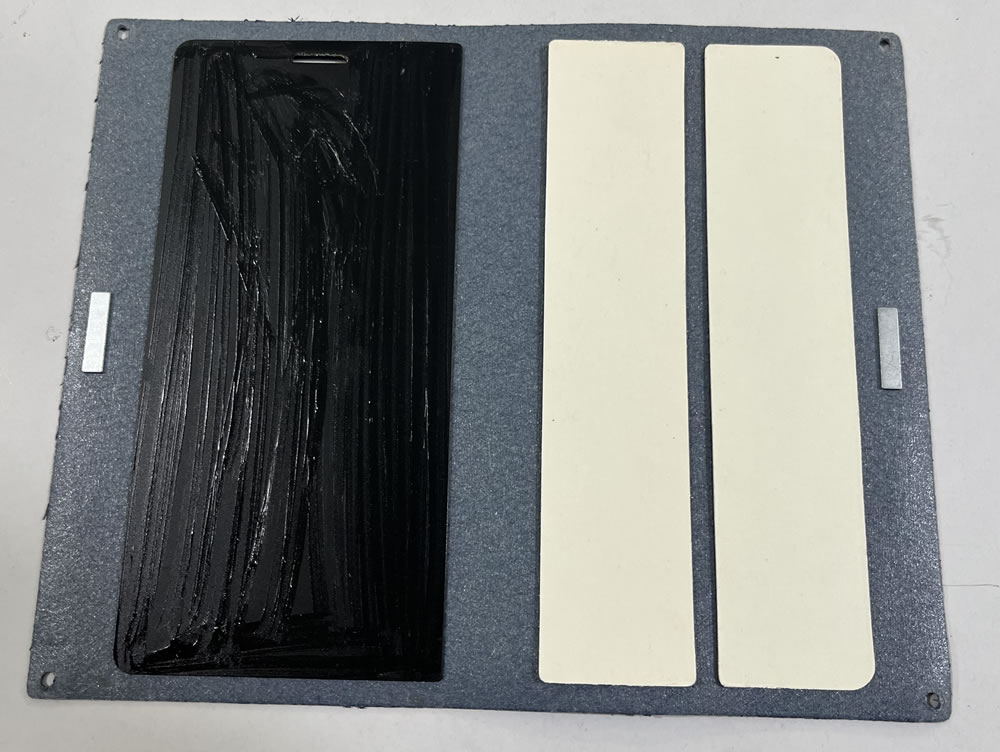

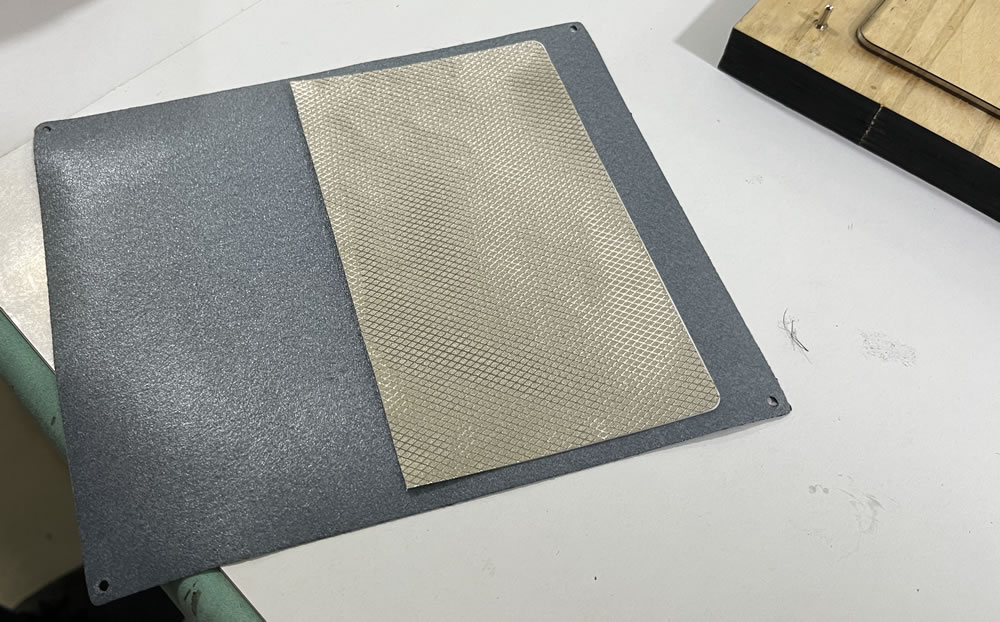

Unlike the outer skin layers, which are cut a single layer at a time to ensure the highest quality needed for exterior layers, several layers of RF Safe shielding are cut simultaneously using a similar press-cutting machine. As the manufacturing process continues, this RF-safe shielding layer will be added by hand with other components required for a finished QuantaCase.

Which we should point out is the most critical layer of all. One of the most essential characteristics of this step is the conductive microwave shielding MUST always cover the entire front of the phone when the case is closed. The whole phone is basically an antenna. Shielding only a portion of the device between you and the transmitter makes no sense at all.. Too many companies claiming to make anti-radiation cases apply cell phone radiation shielding only over the cardboard insert. Quantacase takes exact measurements for each model to apply as much cell phone radiation shielding as possible without reaching the back of the phone. Conductive shielding or metallic or furious materials are NEVER design considerations for the back of the phone, which could affect the output power and signal strength design. Companies that make cell phone radiation shields that incorporate conductive or other signal-impeding materials in their cases simply don’t understand the science of manufacturing effective smartphone radiation shields. What isn’t inside QuantaCase is just as important as what is inside QuantaCase!

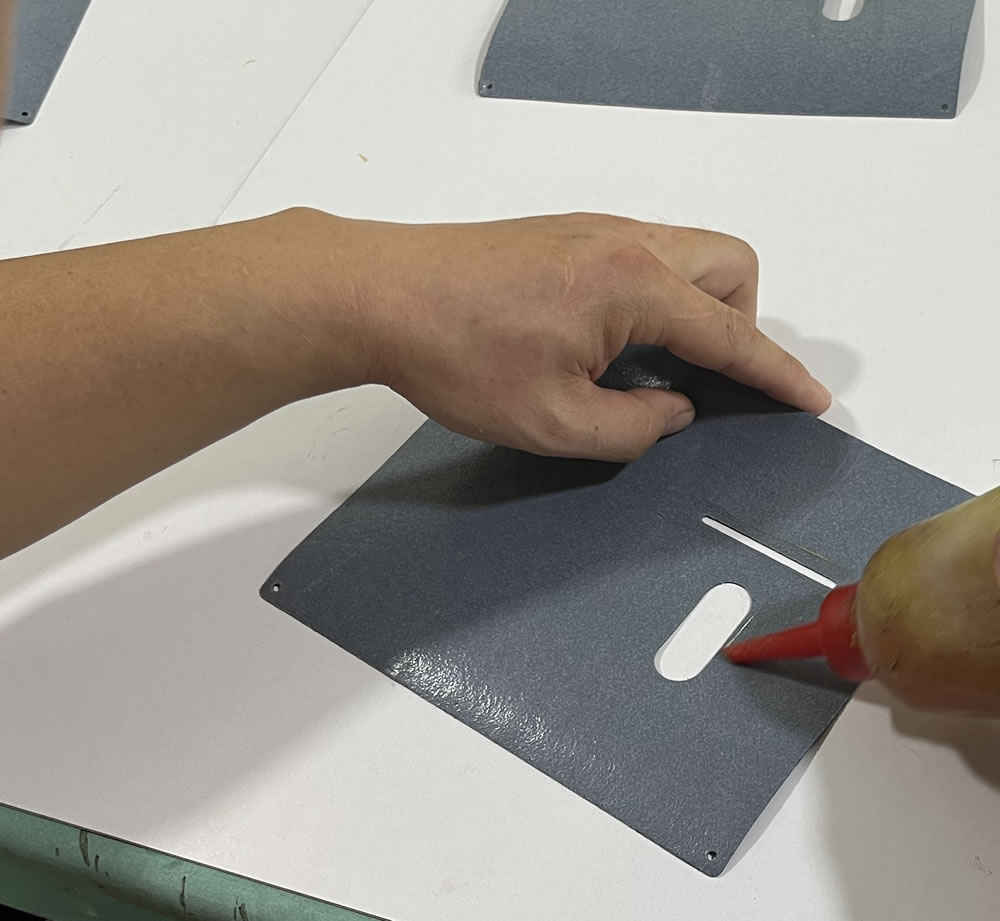

adding glue by hand to add internal components

Adding credit card slot liner by hand

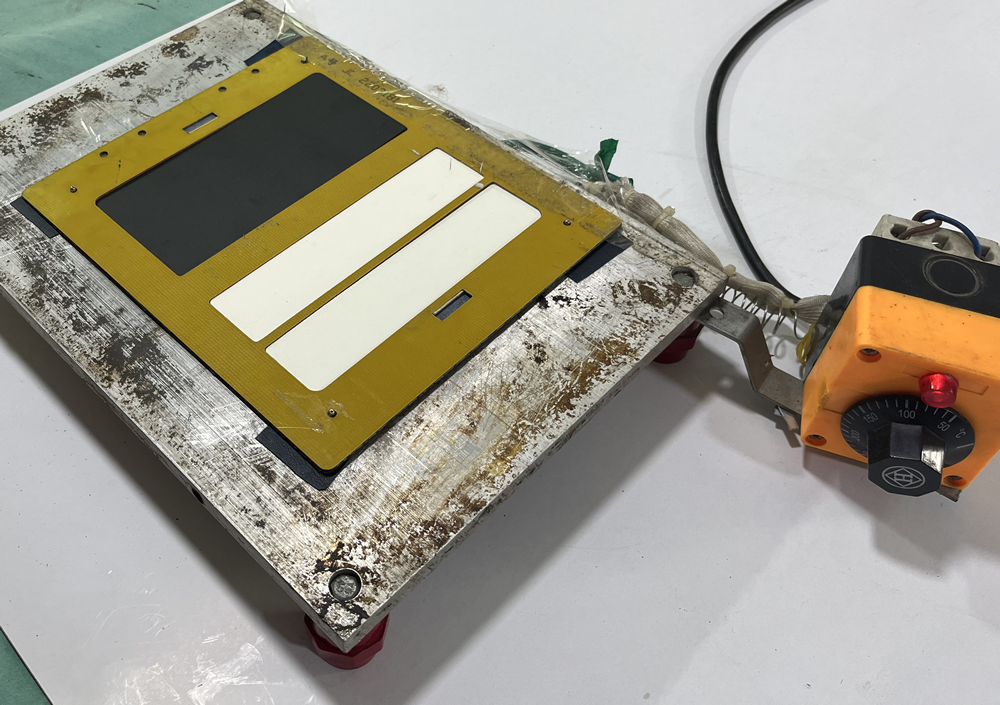

Manufacturing mold assembly is readied for QuantaCase components

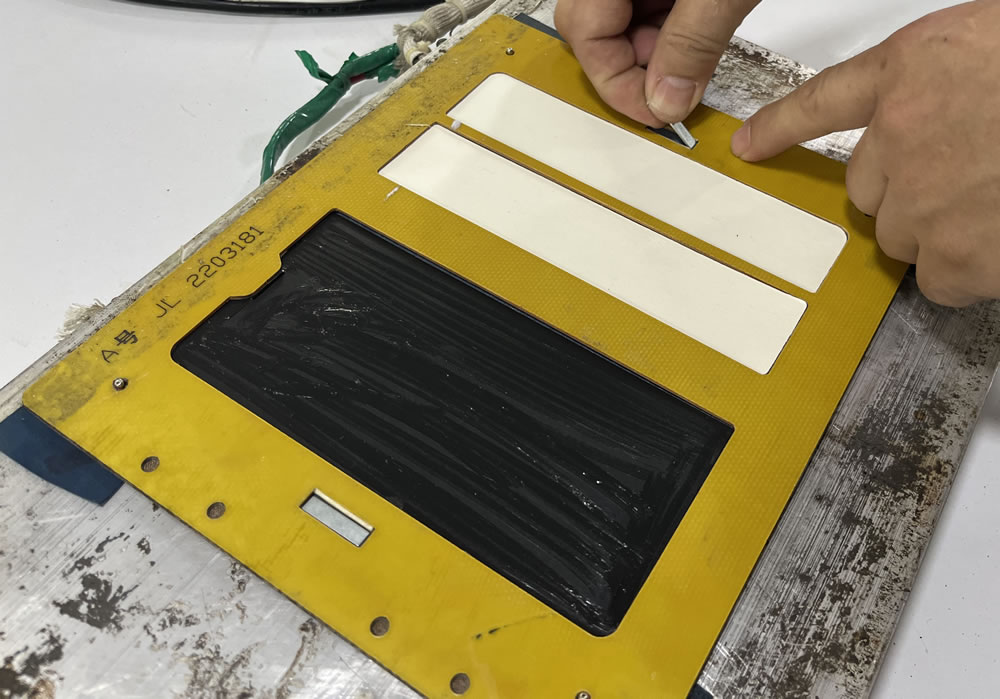

non-conductive components are ready for assembly

Side latch magnets are paced into the manufacturing mold assembly as remaining QuantaCase components are readied for attaching to outer layers.

The press permanently seals the nonconductive support components to the exterior layer.

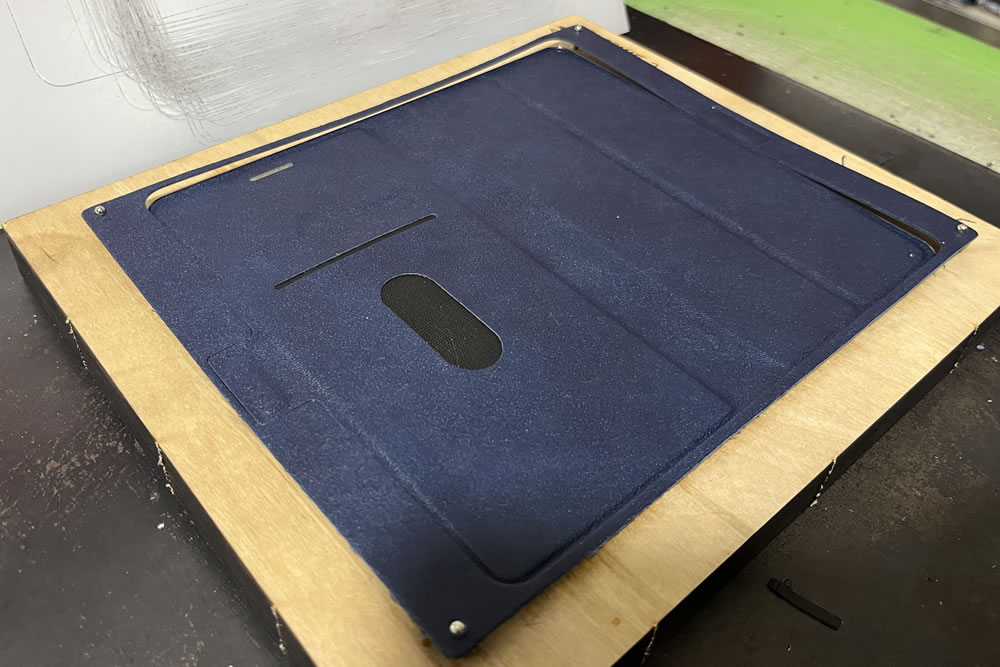

Everything here is transparent to microwaves! Now that things are where they belong, assembling the layers is done using the holes in each corner.

Ready for shielding layer

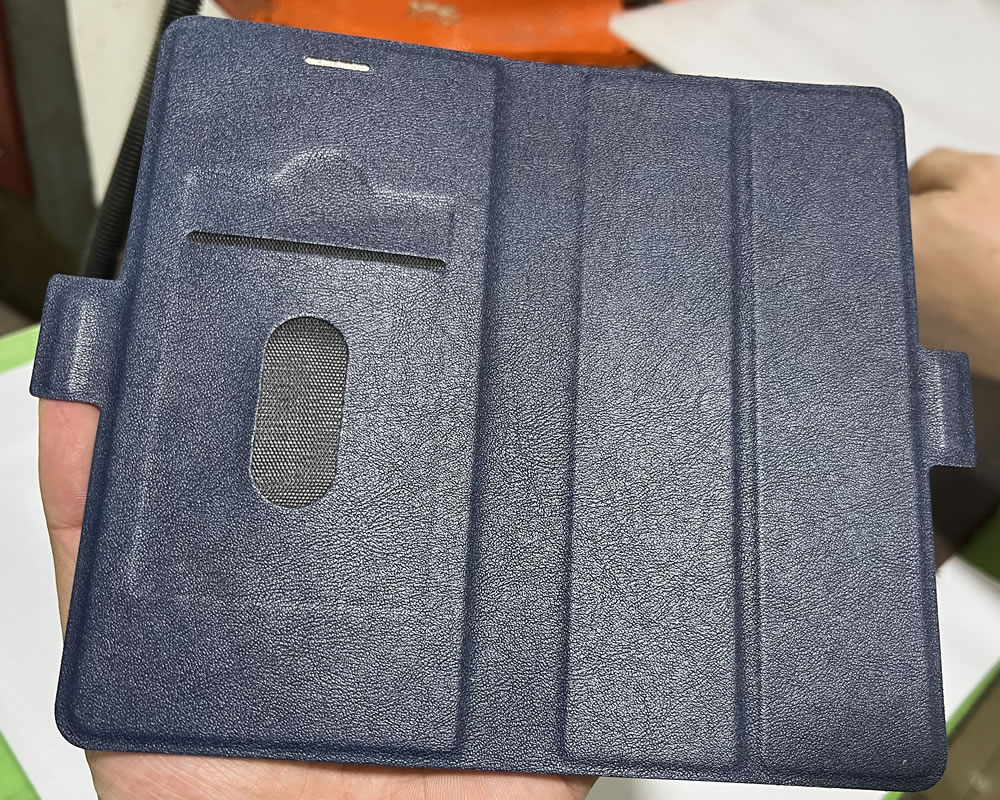

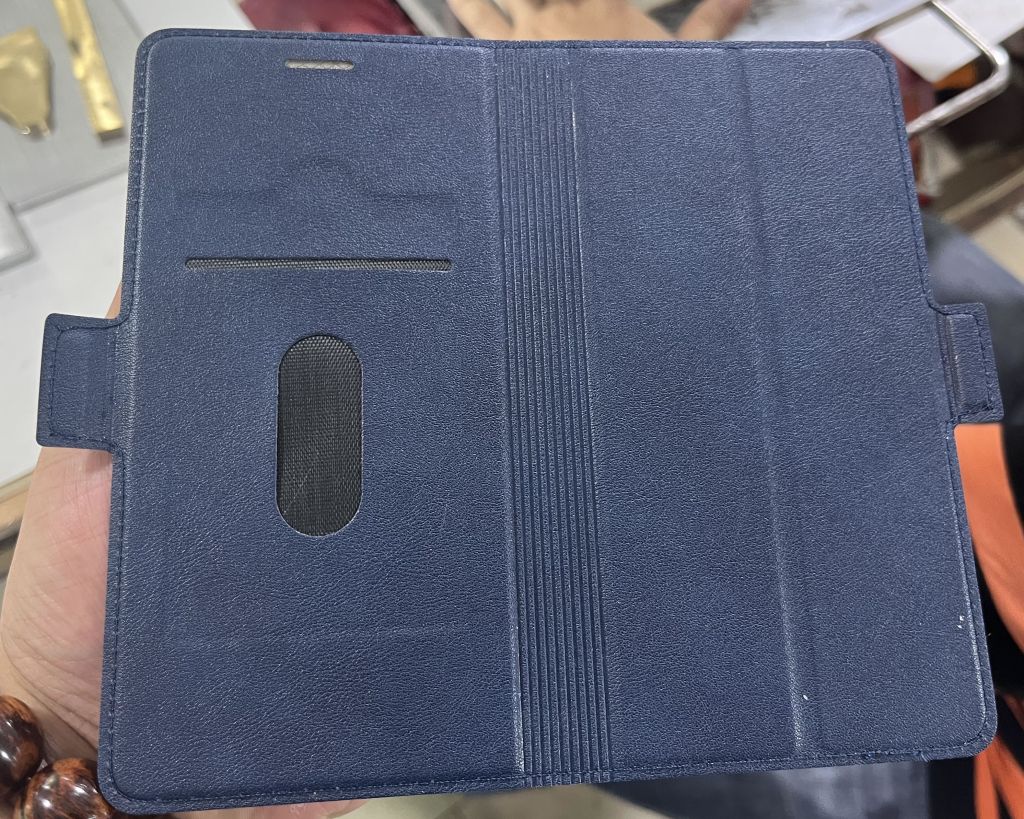

QuantaCase Layers are assembled and ready for the heavy press – Inside case view

QuantaCase Layers are assembled and ready for heavy press. outside case view

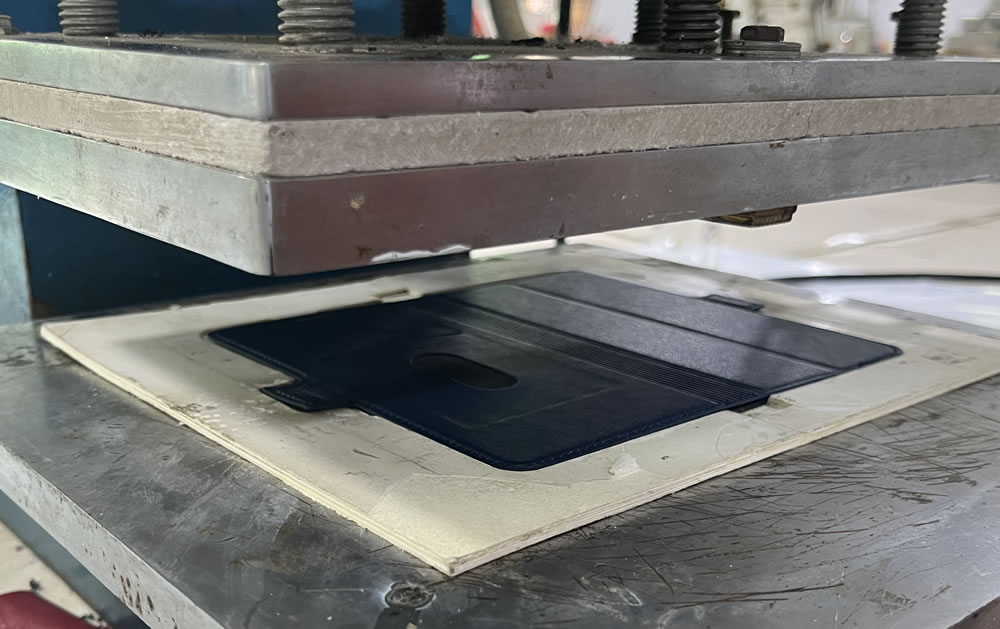

Bringing on the heavy press to seal all the QuantaCase layers together

QuantaCase starts to have some form – an inside view

QuantaCase starts to have some form – an outside view

This is the last time the alignment holes are needed, another press is used to cut the exterior edges to perfection every time!

QuantaCase alignment holes are trimmed off to create the final edge form of the case

cut before edges are sewn

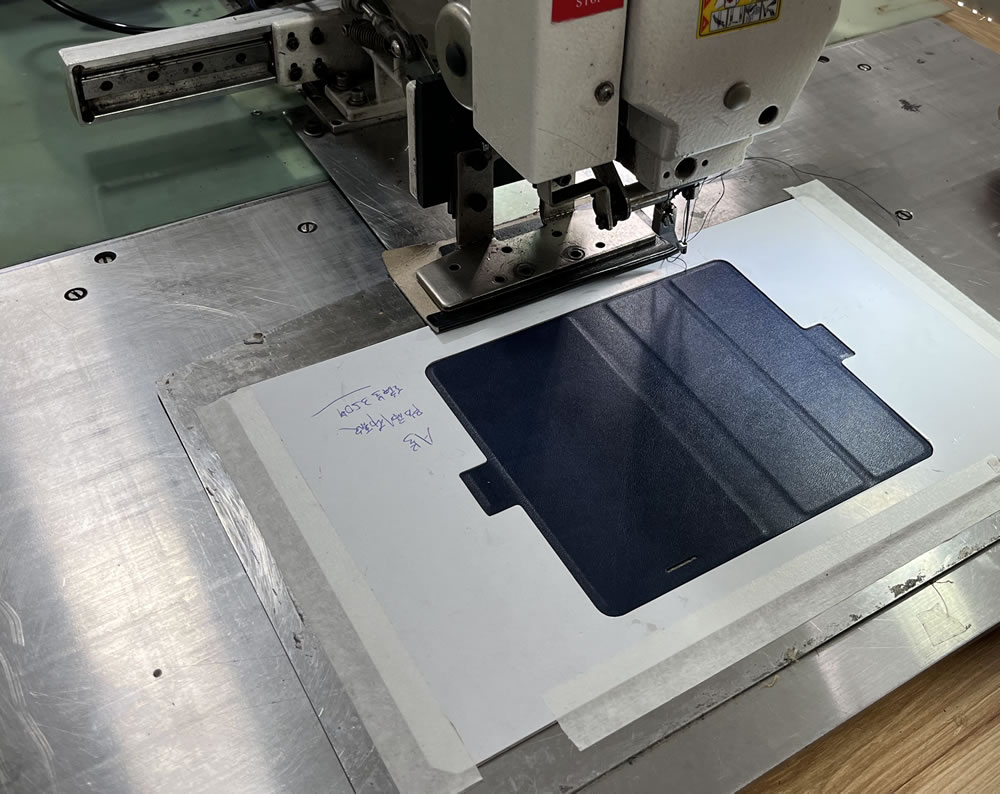

each-quantacase-has-a-program-created-to-get-every-thread-as-perfect-as-possible

quantacase-semi-automatic-sewing-machine-industrial-for-cellphone-cases

quantacase-cellphone-case-press-last-use-of-press-in-design

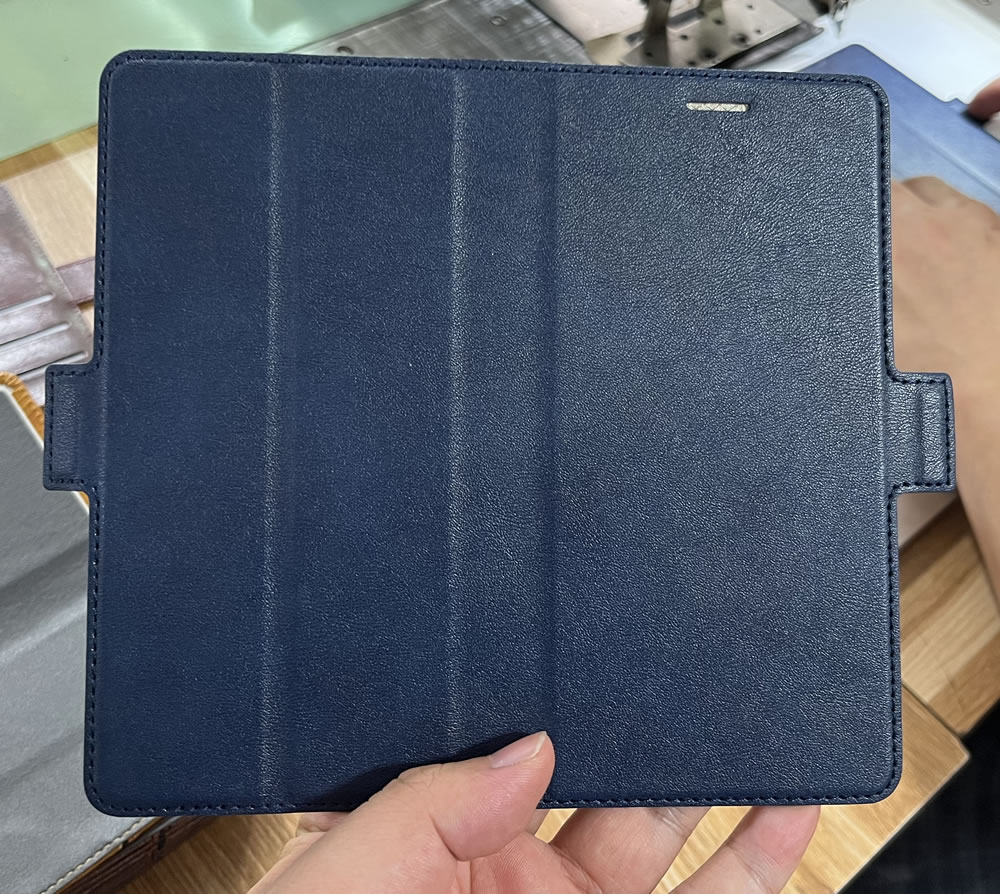

rfsafe-quantacase-radiation-cover-ready-for- next steps

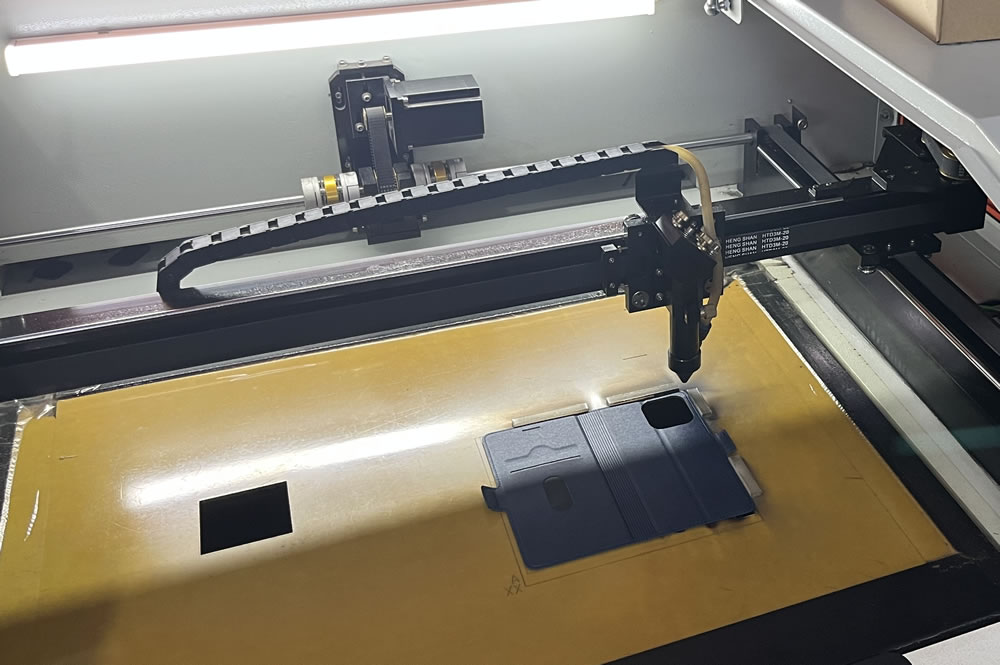

QuantaCase Laser Cut Camera Cutout

quantacase-touchup-done-by-hand-on-every-case quantacase-touchup-for-a-perfect-phone-radiation-case-every-time

QuantaCase Radiation Cover Is Ready For Holder

Through decades of experience, we know what glues to use and how to apply them to make your quantacase last!!

finished-quantacase-back-view

finished-quantacase-inside-view